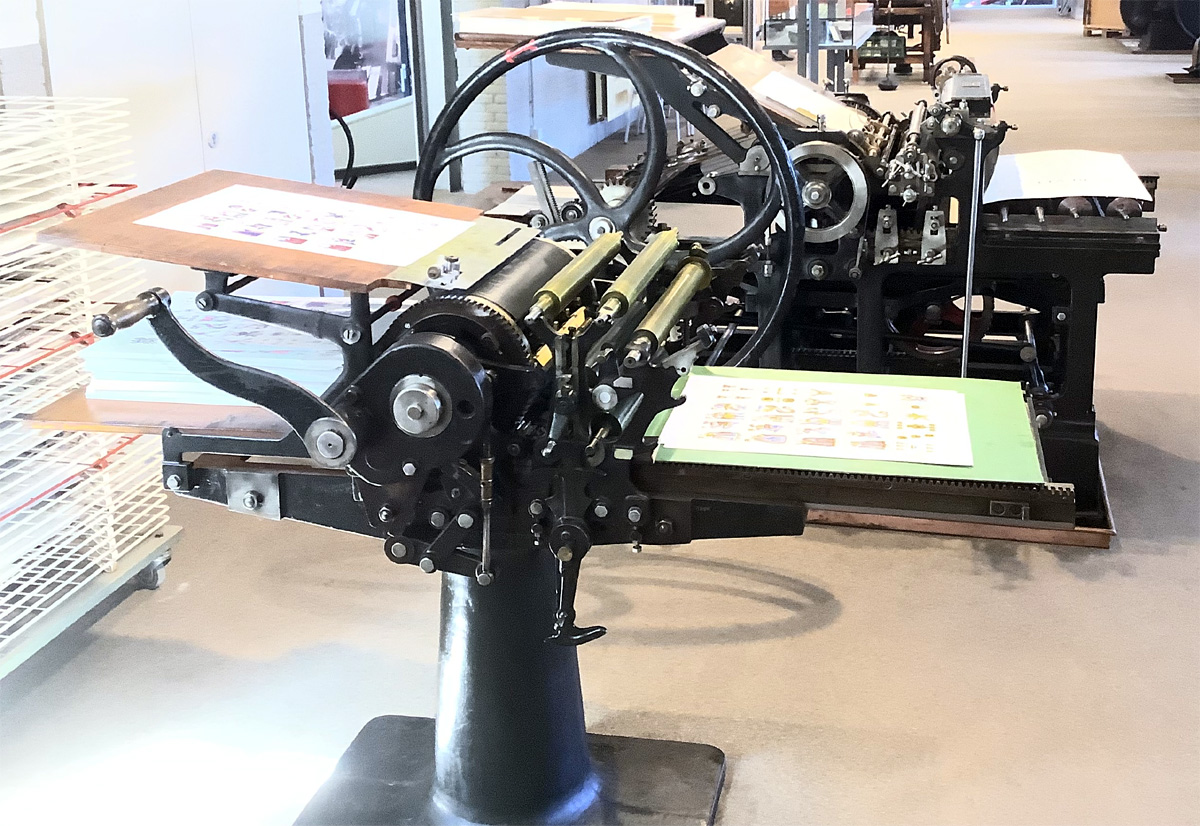

Printing Presses

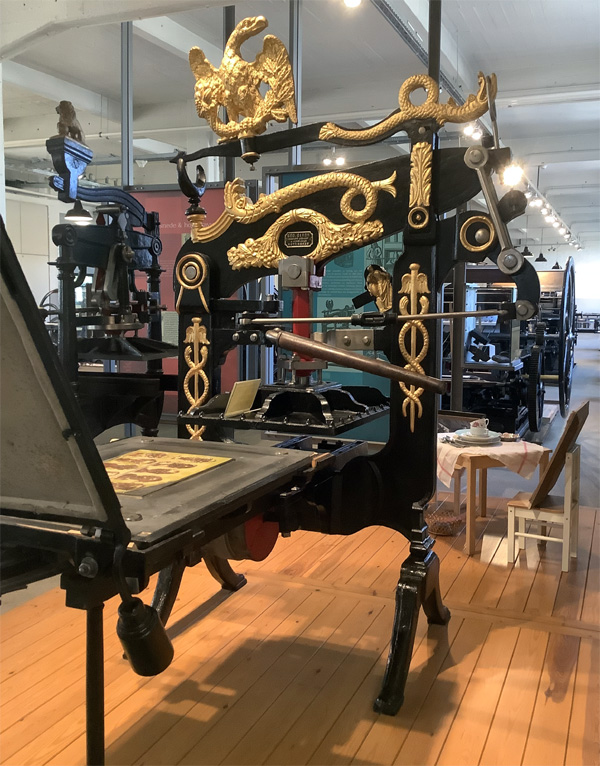

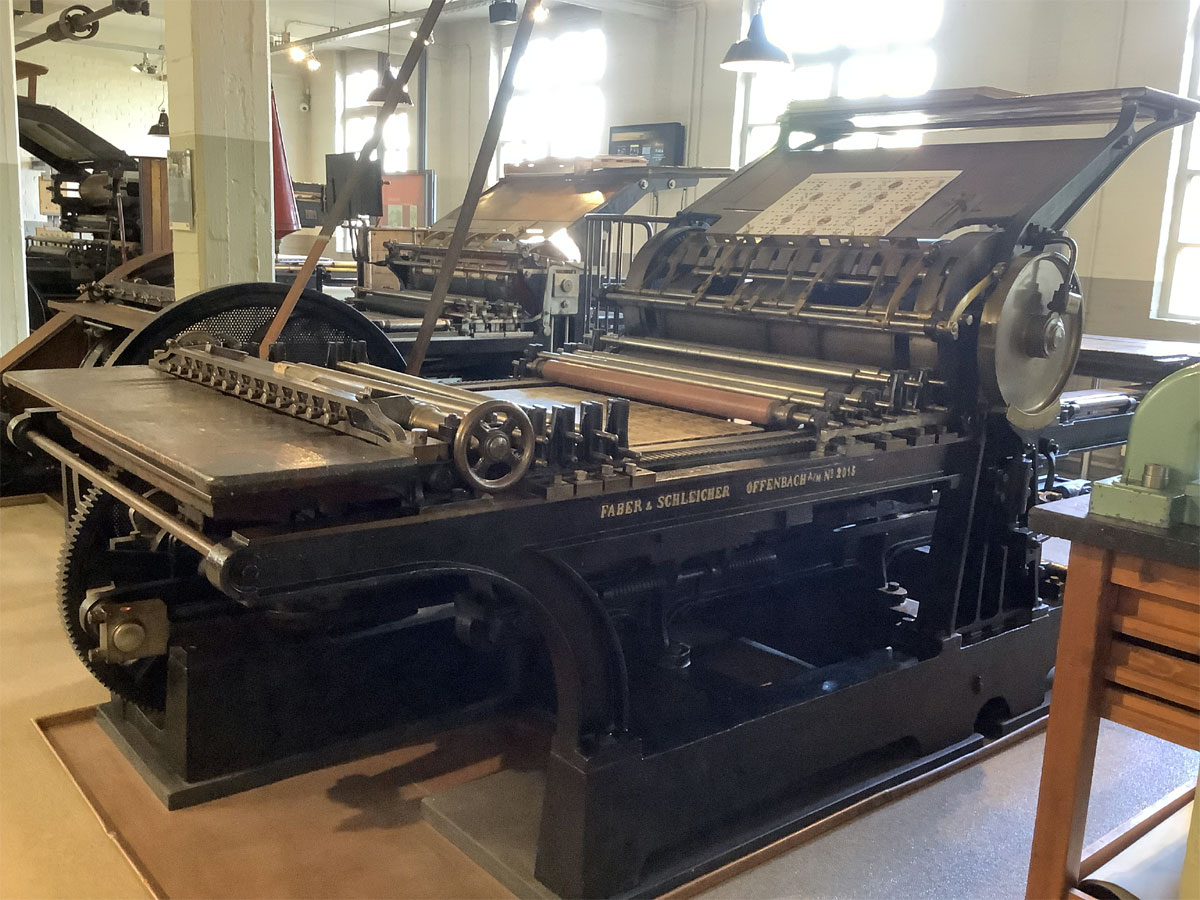

Antique printing presses from the Turnhout Playing Card Museum collection.

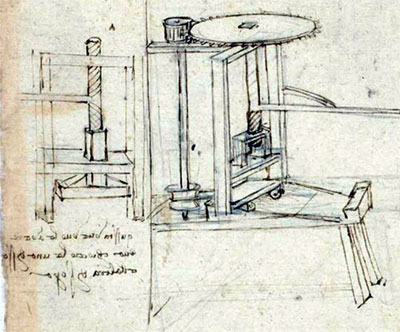

Above: Leonardo da Vinci's design for a printing press c.1480, Codex Atlanticus fol.995►

The Turnhout Playing Card Museum has an impressive collection of antique printing machinery ranging from early hand-operated letterpress and lithographic to steam powered or electric lithographic and offset printing presses. While card making was still done by hand well into the 18th century, various graphical techniques for printing had already been developed in parallel, such as etching or copperplate printing. The new technologies introduced in the second half of the 19th century ultimately led to the triumph of chromolithography. As technology progressed the output and speed increased exponentially, paving the way for Turnhout's leading role in the industry with exports worldwide. There are plenty of information leaflets available in the museum which explain everything and the curator is very knowledgeable.

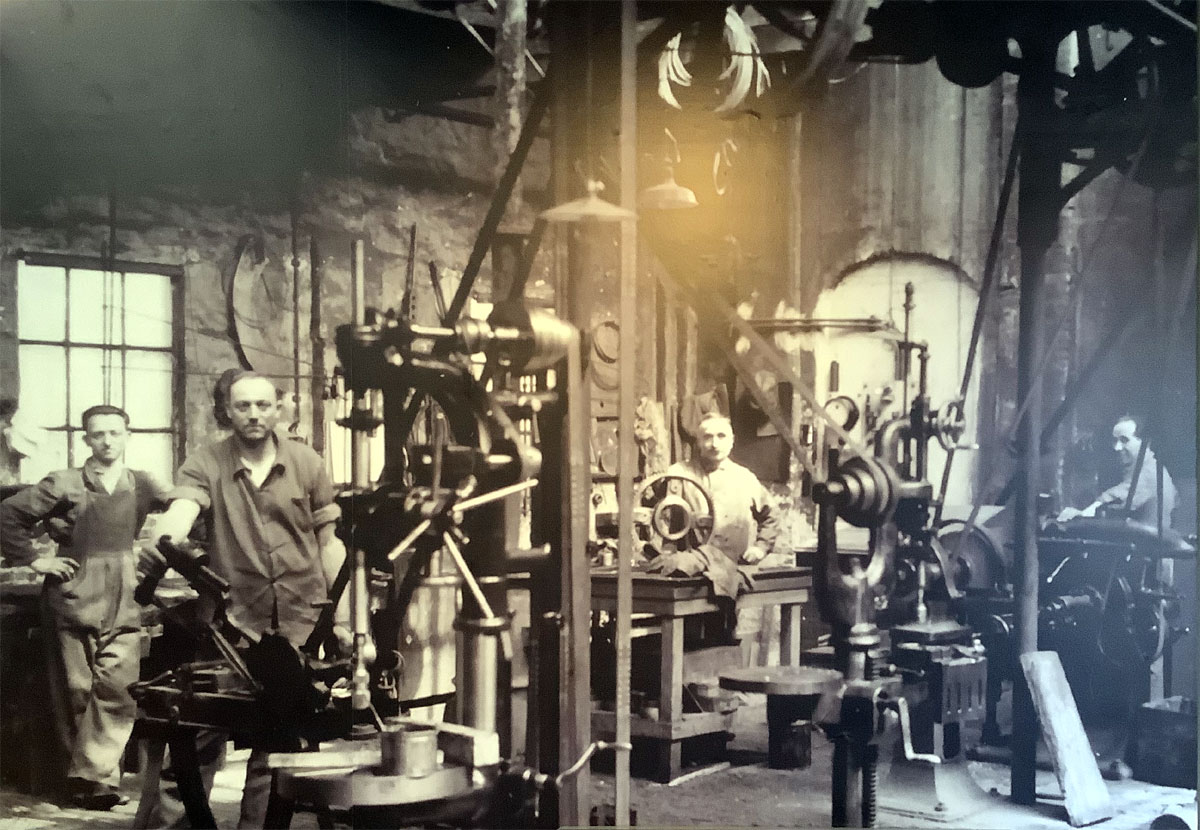

The earliest presses were built from wood and used woodblocks to print from. This way of working did not essentially change until the late 18th century: printed sheets of playing cards were produced manually by pressing the paper onto the blocks after the ink had been rolled on. However, these methods were superceded by innovations. Presses and the blocks began to be made from metal so that higher pressure could be exerted and work could proceed at a faster pace. Even so, a team of two workers produced printed sheets one at a time, working all day. In the early days output was around 500 sheets per day.

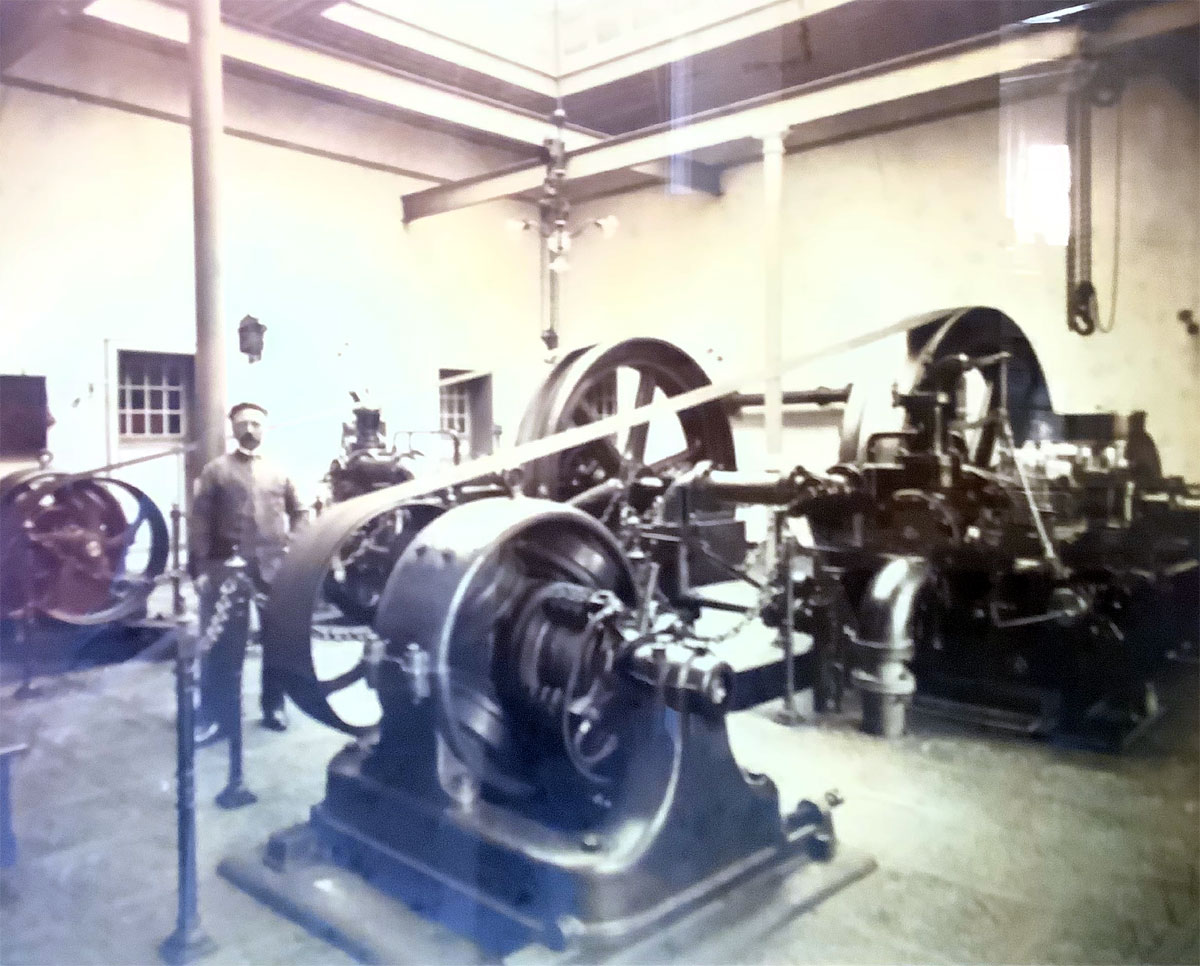

Above: increasing knowledge of mechanics and metallurgy brought innovations in the construction of printing presses so that it became possible to work faster. Images courtesy of the Turnhout Playing Card Museum, Belgium.

The Industrial Revolution brought innovations which made the old manual printing presses obsolete. Following the invention of lithography by Alois Senefelder in the years 1796-1798, printed matter including playing cards was transformed. To begin with, these machines were manually operated, but when connected to a steam engine the machines ran uninterruptedly, even at night-time. Water and ink were automatically spread over the lithographic stone with rollers and much larger print runs became possible, bringing higher profits to the owner. Another advantage of lithography is that if a proof was taken and seen to be defective, the artwork on the stone could be re-touched until everything was ready to go ahead.

How does a lithographic hand press work?

- The printing form (the stone) was put on the wagon.

- The stone was wetted and then inked.

- A sheet of paper was put on the stone, with a few cover sheets for protection.

- The scraper plate was brought down.

- The printer then turned the capstan and pulled the wagon under the scraper.

- The lithographer opened the scraper, the wagon was pulled back and the paper that was now printed was carefully taken off the stone.

- The printed paper was hung up to dry.

Above: all images courtesy of the Turnhout Playing Card Museum, Belgium.

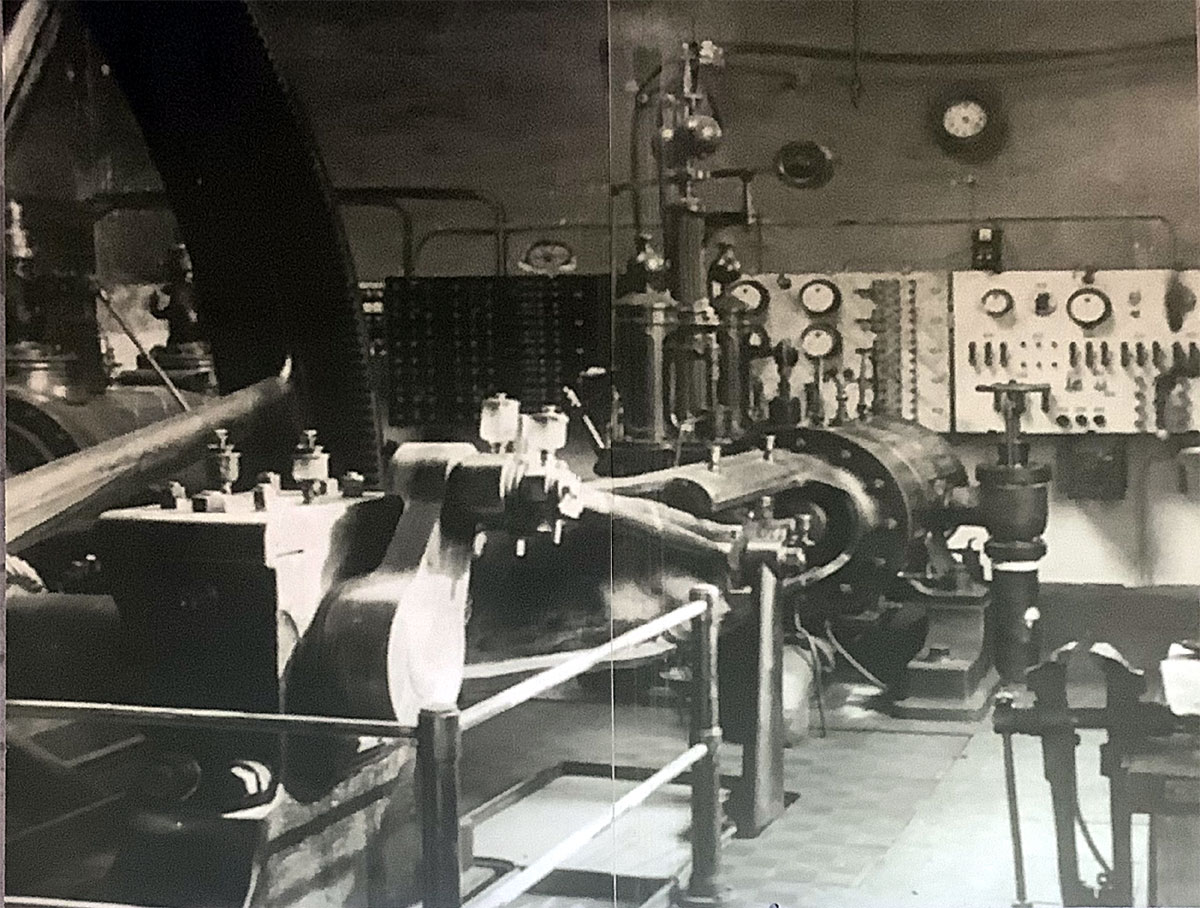

Photographic Archives

With the steam engine it became possible to use bigger machines that were too heavy to be powered manually. The steam engine was often accommodated within a separate building with a boiler and a tall chimney. A large driving wheel was connected to the various machines via a drive shaft and belts. Much of the traditional craftsmanship and artisan skill disappeared to be replaced by engineers, technicians and machine minders. Inside the factory environment - typically a large hall - the machinery was aligned as directly as possible with the energy source.

The Steam Engine

The steam engine provided many benefits to the playing card factory, such as heating and the drying of printed paper. The whistle, also powered by steam, marked the beginning and end of working hours. The steam engine was the force behind the so-called Industrial Revolution. Without it, industrialisation would not have been possible. Later on it also enabled the generation of electric power. See the steam engine►

Above: all images by kind permission of the Nationaal Museum van de Speelkaart / Turnhout Playing Card Museum, Druivenstraat 18 B-2300 Turnhout, Belgium.

References

Museum information sheets:- Turnhout, City of Playing Cards

- Woodcuts

- Printing Presses

- Lithography

- Steam Engines

By Simon Wintle

Spain • Member since February 01, 1996 • Contact

I am the founder of The World of Playing Cards (est. 1996), a website dedicated to the history, artistry and cultural significance of playing cards and tarot. Over the years I have researched various areas of the subject, acquired and traded collections and contributed as a committee member of the IPCS and graphics editor of The Playing-Card journal. Having lived in Chile, England, Wales, and now Spain, these experiences have shaped my work and passion for playing cards. Amongst my achievements is producing a limited-edition replica of a 17th-century English pack using woodblocks and stencils—a labour of love. Today, the World of Playing Cards is a global collaborative project, with my son Adam serving as the technical driving force behind its development. His innovative efforts have helped shape the site into the thriving hub it is today. You are warmly invited to become a contributor and share your enthusiasm.

Related Articles

Cartes Universelles

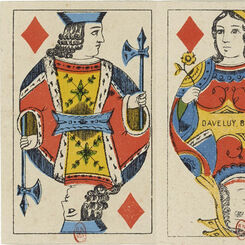

Four Continents fantasy playing cards by Daveluy, Bruges, Belgium, 1860-1885.

Lithographic Stone

Historic lithographic stone from the Fournier playing card factory, c.1888.

Cartes Marbrées

A provincial variant of the French ‘Paris’ pattern produced by Daveluy c.1850-1895.

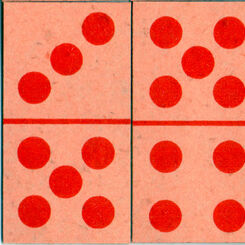

Domino Cards, c.1890

Domino Cards by Mesmaekers Frères, c.1890

Anon Spanish Cards c.1875

Spanish-suited playing cards made in Belgium by Mesmaekers Frères, c.1875.

Manuf’d for L.N. Mann

Standard English pattern manuf’d for L.N. Mann by Van Genechten, c.1890.

Carta Mundi

Carta Mundi was founded in Turnhout on 27 June 1970 by pooling the production and sales facilities o...

Van Genechten

A. Van Genechten ran a flourishing business, supplying various kinds of cards both inside the countr...

Chromolithography

Colour lithography was invented in 1798 by a Bavarian actor and playwright named Alois Senefelder (1...

Printing of Playing Cards: Stencilling

Printing of Playing Cards :: Stencilling can usually be detected by observing the outlines of the co...

Printing of Playing Cards: Letterpress

Some notes on the manufacture of playing cards taken from Thomas De la Rue's patent, 1831.

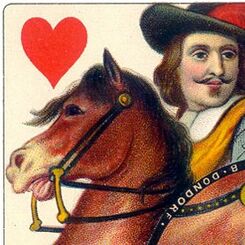

Dondorf

The luxury playing card factory founded in Frankfurt am Main by Bernhard Dondorf in 1833 existed for...

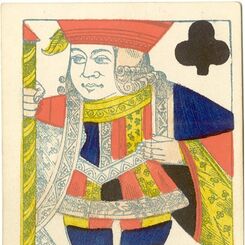

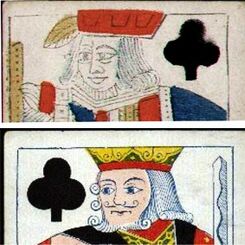

Mesmaekers & Moentack, c.1860

The Mesmaekers firm had been established in Turnhout in 1859 by the partnership of Gustaaf Mesmaeker...

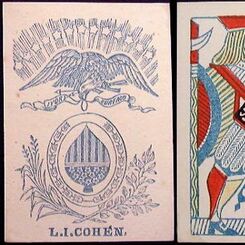

Lewis I. Cohen

Lewis I. Cohen made his first deck of cards in 1832. In 1835 Mr Cohen invented a new machine to prin...

Léonard Biermans, Turnhout

Léonard Biermans had been employed by Brepols from 1871-1874 before opening his own playing card fac...

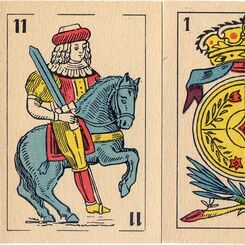

A Todos Alumbra

40-card “A Todos Alumbra - Naypes Refinos” pack manufactured by Léonard Biermans, Turnhout.

Spanish Cards c.1920

Spanish-suited Playing Cards manufactured by Van Genechten, c.1920.

De La Rue

De La Rue introduced letter-press printing into playing card production and his patent was granted i...

Belgian Playing Cards

Belgian cardmakers have been actively designing and exporting playing cards since the 14th century. ...

Portuguese Type Playing Cards c.1860

10 cards from a pack of later Portuguese ‘Dragon’ type cards from c.1860, with the Maid of batons ab...

Most Popular

Our top articles from the past 60 days